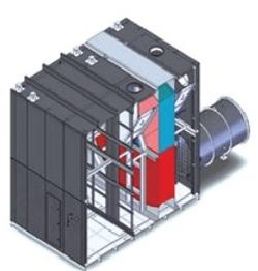

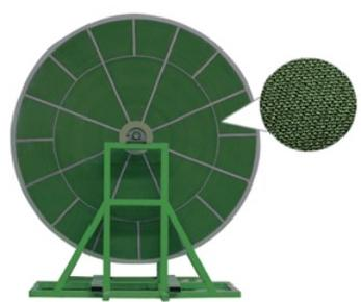

Zeolite concentrated rotary RTO

Key words:

Biochemical treatment equipment

Flotation equipment

Classification:

Zeolite concentrated rotary RTO

Exhaust treatment of impurities such as nitrogen, sulfur and chlorine in exhaust gas; Exhaust treatment of resin, rubber, tire and other products in the production process; Exhaust treatment of various painting workshops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.); Exhaust treatment of aluminum profile production, coating processing technology, etc.; Exhaust treatment of various electronic products manufacturing processes; exhaust treatment of various printing workshops (gravure printing, building decoration material printing, and other printing processes); exhaust treatment of semiconductor integrated circuits and liquid crystal display (LCD) manufacturing processes; exhaust treatment of lithium-ion battery manufacturing (electrode formation process, electrolyte filling process).

Related Products

Get a Product Quote

Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.

Contact: Mr. Dong+86-13928844138 +86-13774077867

E-mail:1017645596@qq.com

Address: Industrial Plant in the Western Half of Building E2, Intelligent Industrial Park, Jingshan Economic Development Zone, Jingmen City, Hubei Province

Official website:http://en.haojie668.com/

Focus on us

Sweep Code Add

Copyright©2024 Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.