Papermaking wastewater treatment project

Key words:

Biochemical treatment equipment

Flotation equipment

Classification:

Papermaking wastewater treatment project

Case analysis

Product Category: Papermaking Sewage Treatment Engineering

Pollution control type: wastewater from papermaking and daily sewage treatment

Treatment scale: daily treatment capacity of 4000 tons. Implementation standard: comprehensive primary emission standard

Treatment process: the combination of hydrolysis acidification and biological contact oxidation

Project introduction: papermaking sewage treatment project, the water treatment volume of the project is 4000m °/d, and the treatment effect reaches the discharge standard of papermaking wastewater (GB3544_2008).

Characteristics and difficulties of papermaking wastewater treatment

Papermaking wastewater has high pollutant concentration, complex composition and poor biodegradability. It is characterized by a large amount of wastewater, high COD mass concentration, more fiber suspended solids in wastewater, and the combination of divalent sulfur elements, high chroma, and the odor of thiols. If it is not treated or not treated immediately discharged into water or used for irrigation, it will pollute the environment and affect people's health.

Solutions and technical features

According to the actual investigation of the paper mill, through on-site investigation and data search, as well as the comprehensive analysis of monitoring data from the local environmental monitoring station, the technical team of our company adopted the process flow of "pretreatment-physicochemical treatment and chemical treatment" for the paper mill, which effectively solved the treatment problem of papermaking wastewater and domestic sewage in the paper mill.

After removing coarse solid particles through the grid, the raw sewage enters the regulating tank to adjust the water volume and pH, then is lifted to the sedimentation tank by the lifting pump, and then is anaerobic treated through the hydrolytic acidification tank, and then is aerobic treated through the contact oxidation tank, and the treated sewage is discharged through the secondary sedimentation tank. The proposed project is cost-effective and reliable in operation.

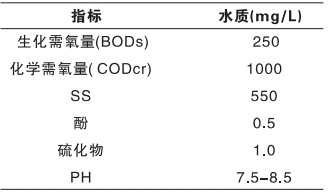

Inlet water quality

Effect after treatment

The sewage treatment system designed for the paper mill has good effluent quality, and the main water quality indicators can meet the discharge standards, which can well adapt to the water quality problems of the influent. The effluent of the system can meet the discharge standard of papermaking wastewater (GB344-2008), which effectively solves the reality that some indicators in this kind of wastewater are difficult to deal. According to the actual requirements and design process, the method of hydrolysis acidification biological contact oxidation is used to improve the water quality, meet the requirements of effluent standard and ensure the long-term stable operation of the sewage treatment system.

Related Products

Get a Product Quote

Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.

Contact: Mr. Dong+86-13928844138 +86-13774077867

E-mail:1017645596@qq.com

Address: Industrial Plant in the Western Half of Building E2, Intelligent Industrial Park, Jingshan Economic Development Zone, Jingmen City, Hubei Province

Official website:http://en.haojie668.com/

Focus on us

Sweep Code Add

Copyright©2024 Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.