Molecular sieve zeolite wheel adsorption concentration device

Key words:

Biochemical treatment equipment

Flotation equipment

Classification:

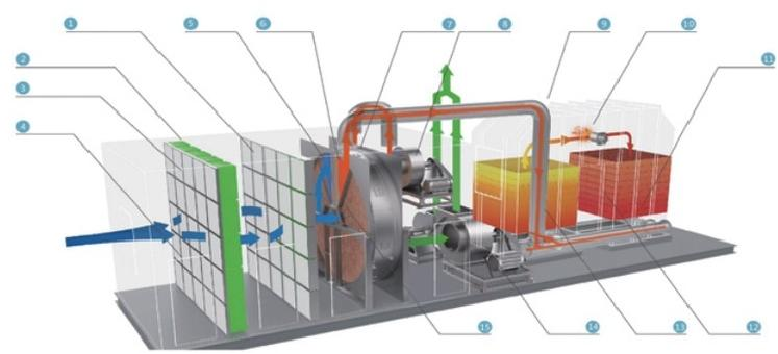

Molecular sieve zeolite wheel adsorption concentration device

Application Industry/Appication industy

Molecular sieve adsorption and concentration system is mainly used for exhaust treatment of various painting workshops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.), exhaust treatment of various printing workshops (gravure printing, building decoration materials printing, other printing processes), aluminum profile production, coating process, exhaust gas treatment, exhaust gas treatment of various electronic product manufacturing processes, semiconductor integrated circuits, liquid crystal display (LCD) manufacturing process exhaust gas treatment, lithium-ion battery manufacturing exhaust gas treatment (electrode molding process, electrolyte filling process), exhaust gas treatment resin, rubber, tire production process, auto repair shops, clothing dry cleaners, etc. Volatile organic compounds waste gas treatment.

1. High-efficiency filter 2. Medium-efficiency bag-type filter 4. Access door 5. Cooling zone attached area 7. Rotary wheel 8. Desorption fan 9.RTO 10. Burner 11.RTO switching valve 12. Regenerator 13. Regenerator 14. Adsorption fan 15. Adsorption zone

Related Products

Get a Product Quote

Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.

Contact: Mr. Dong+86-13928844138 +86-13774077867

E-mail:1017645596@qq.com

Address: Industrial Plant in the Western Half of Building E2, Intelligent Industrial Park, Jingshan Economic Development Zone, Jingmen City, Hubei Province

Official website:http://en.haojie668.com/

Focus on us

Sweep Code Add

Copyright©2024 Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.