Low temperature evaporation equipment 2

Key words:

Biochemical treatment equipment

Flotation equipment

Classification:

Low temperature evaporation equipment 2

Model | D10L-H | D20L-H | D50L-H | D100L-H | D200L-H |

Processing capacity | 10L/h | 20L/h | 50L/h | 100L/h | 200L/h |

Concentration method | Low-temperature distillation under reduced pressure | ||||

Heating mode | Air energy heat transfer mode | ||||

Object waste | water-soluble waste liquid | ||||

Power | 380V 50Hz | ||||

Electrical capacity/total current | 10A | 15A | 22 A | 40A | 80 A |

Power | 3.5KW | 5KW | 8KW | 15KW | 30KW |

Consumables | Defoamer (if necessary) | ||||

Product Weight | 260KG | 360KG | 500KG | 750KG | 1300KG |

Host size (mm) | 900*1000*1600 | 1050*1050*1600 | 1400*1500*1600 | 2000*2000*1800 | 3100*2900*2100 |

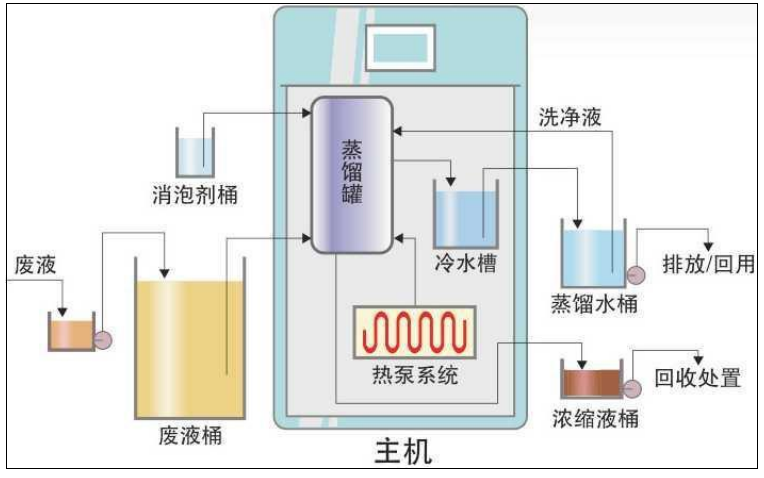

Description of work steps:

1. Suction the waste liquid from the waste liquid barrel;

2. In order to suppress the foam generated when boiling, absorb the defoamer;

3. Depressurize the distillation tank to a vacuum state;

4. Heating distillation tank waste liquid, low temperature boiling 30°C;

5. The generated vapor is cooled and becomes distilled water;

6. The remaining concentrated waste liquid in the distillation tank is repeatedly distilled several times.

After that, store it in the concentrated liquid tank;

7. Distilled water is temporarily stored in the cold water tank in the machine, and then stored again

Distilled water bucket stored outside;

8. Automatic cleaning, the machine outside the distilled water again

The retort.

1. Achieve a high concentration rate, significantly reducing the cost of waste liquid treatment.

Performance value: water-soluble waste liquid can be concentrated to 1/20

2. All kinds of water-soluble waste liquid can correspond

Treatment performance: developer for PS version, water-based varnish cleaning waste liquid, dampening water waste liquid, flexo printing waste liquid, cutting oil (water soluble

sex), water-based paint waste liquid, food waste liquid, etc.

3. With the combination of other wastewater treatment equipment, can achieve higher environmental requirements

Convenience and economy

1.24 hours of continuous automatic operation to reduce the labor load, without the need for special care

2. The automatic cleaning function of the stowage distillation tank saves time and effort.

3. The touch screen improves the operation performance, with alarm function, easy to operate

4. Small design does not need to consider setting up places

5. According to the amount of wastewater selection is convenient, there are 5 liters, 10 liters, 20 liters, 50 liters, 100 liters, 200 liters of products

Safety and environmental protection

1. Low temperature decompression distillation method, no fire source, no high temperature and high heat, no explosion-proof

2. The heat pump system only needs a small amount of electricity and defoamer

3. Accessories selection of world, domestic famous brand, long service life

4. Do not produce peculiar smell and harmful substances in the working process

5. Produced distilled water in line with the national standard "integrated sewage discharge standards", can be discharged or reuse standards

Related Products

Get a Product Quote

Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.

Contact: Mr. Dong+86-13928844138 +86-13774077867

E-mail:1017645596@qq.com

Address: Industrial Plant in the Western Half of Building E2, Intelligent Industrial Park, Jingshan Economic Development Zone, Jingmen City, Hubei Province

Official website:http://en.haojie668.com/

Focus on us

Sweep Code Add

Copyright©2024 Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.