Pickling sewage treatment works

Release time:

2024-06-25

Pickling process is an essential process for galvanizing, electroplating, metal products, machinery manufacturing, steel, metal materials and other industries. Pickling wastewater usually includes: deoiling (grease) wastewater; hydrochloric acid, sulfuric acid, nitric acid, hydrofluoric acid, phosphoric acid and other monoacid or several mixed acid wastewater; flushing wastewater and purification wastewater. According to different products, enterprises in various industries add chemical additives and other auxiliary materials in the degreasing and phosphoric acid purification process. Local environmental protection bureaus formulate different discharge standards for different types of enterprises according to the functional zoning of local waters. In the same region, different industries have different emission substances and emission standards. Pickling enterprises must formulate treatment modes and specific contents according to the emission standards.

Case analysis

CASE ANALYSIS

Product classification: Pickling sewage treatment engineering

Project Name: Sewage Treatment Project of a Metal Enterprise in Dongguan

Pollution control type: pickling wastewater and daily sewage treatment

Processing scale: daily processing capacity of 80 tons

Implementation of standards: integrated emission standards

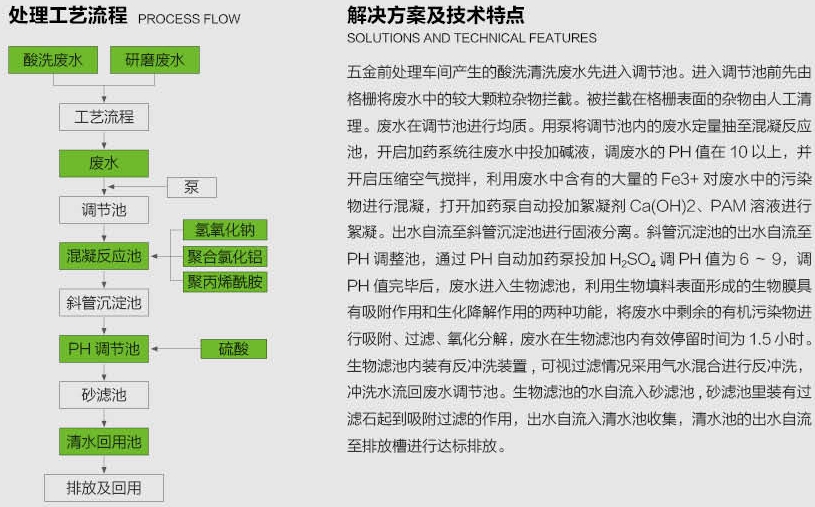

Treatment process: using coagulation sedimentation inclined tube sedimentation quartz filtration treatment process

Project Description: Pickling Sewage Treatment Project, the treatment water volume of the project is 80m ³/d, and the treatment effect reaches the national first-class discharge standard.

Characteristics and difficulties of pickling wastewater treatment

CHARACTERISTICS AND DIFFICULTIES OF PICKLING WASTEWATER TREATMENT

Pickling process is an essential process for galvanizing, electroplating, metal products, machinery manufacturing, steel, metal materials and other industries. Pickling wastewater usually includes: deoiling (grease) wastewater; hydrochloric acid, sulfuric acid, nitric acid, hydrofluoric acid, phosphoric acid and other monoacid or several mixed acid wastewater; flushing wastewater and purification wastewater. According to different products, enterprises in various industries add chemical additives and other auxiliary materials in the degreasing and phosphoric acid purification process. Local environmental protection bureaus formulate different discharge standards for different types of enterprises according to the functional zoning of local waters. In the same region, different industries have different emission substances and emission standards. Pickling enterprises must formulate treatment modes and specific contents according to the emission standards.

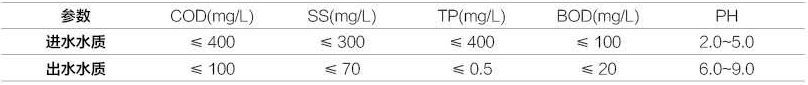

Inlet water quality and outlet water quality

WATER QUALITY AND WATER QUALITY

Effect after treatment

THE EFFECT AFTER TREATMENT

The sewage treatment system designed for the metal enterprise has good effluent quality, and the main water quality index can meet the discharge standard, which can well adapt to the unstable influent water quality. The effluent of the system can meet the comprehensive sewage discharge standard, which effectively solves the problem of not meeting the standard. According to the actual requirements and design process, the treatment process of coagulation sedimentation inclined tube sedimentation quartz filtration is adopted to improve water quality, meet the requirements of effluent standards and ensure the long-term stable operation of the sewage treatment system.

Tag:

Related Cases

undefined

Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.

Contact: Mr. Dong+86-13928844138 +86-13774077867

E-mail:1017645596@qq.com

Address: Industrial Plant in the Western Half of Building E2, Intelligent Industrial Park, Jingshan Economic Development Zone, Jingmen City, Hubei Province

Official website:http://en.haojie668.com/

Focus on us

Sweep Code Add

Copyright©2024 Jingshan Haojie Intelligent Environmental Protection Machinery Technology Development Co., Ltd.